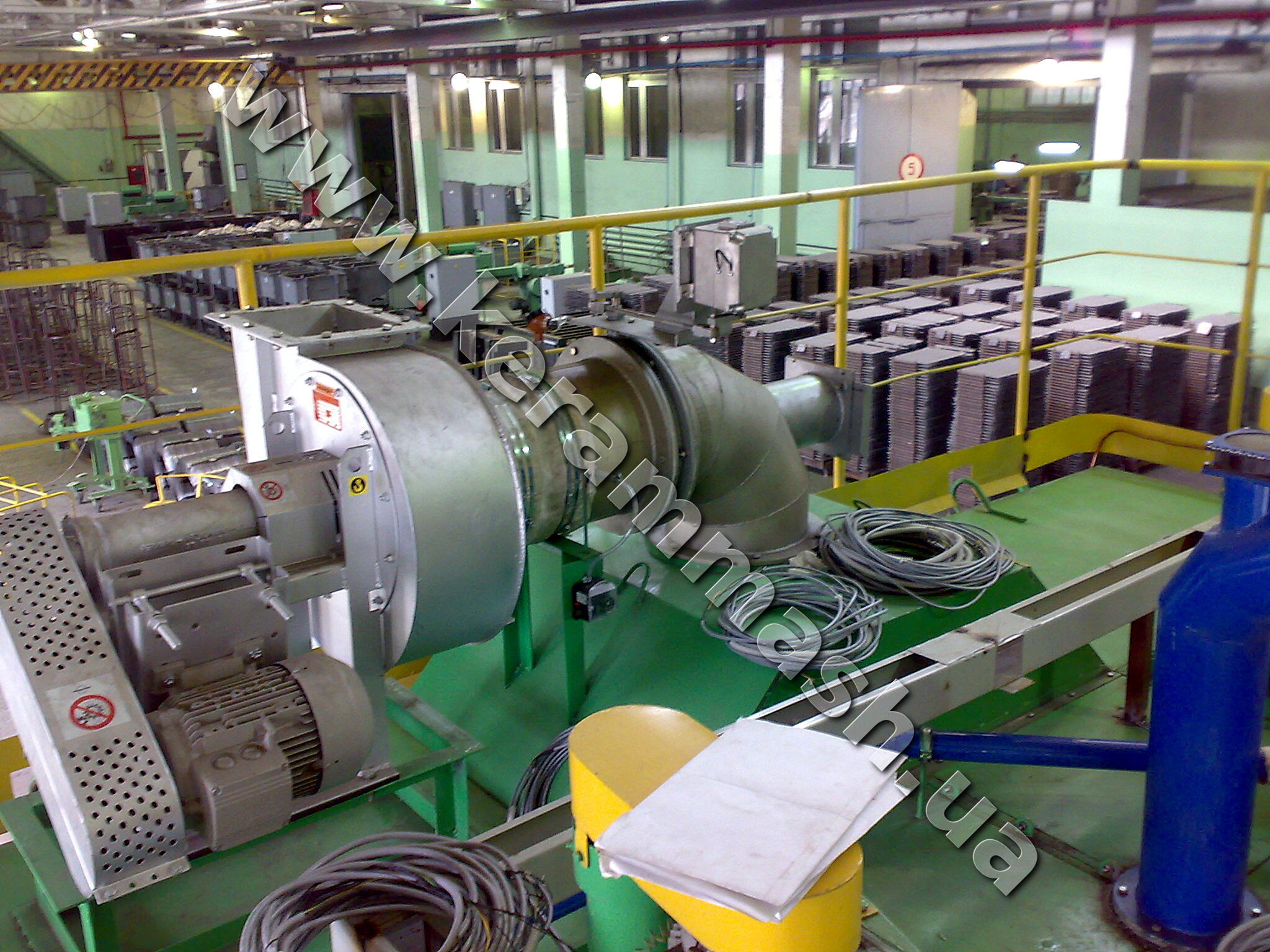

Thermal equipment manufactured under the two brands.

Series ТермоГаз ®

[ ThermoGas ] — the furnaces gas heated, equipped with the most modern

heating systems (Eclipse, WS, Kromschröder), shut-off and control devices (Kromschröder, Termobrest), automatic systems

(Siemens, Ascon) and refractory insulation (Nutec Europe, Thermal Ceramics, RATH, Calderis). Furances series TermoGaz

have excellent energy-saving efficiency, meet European safety and emissions standards. Depending on modification and

application such furnaces may have:

- System with high-velocity or flat-flame burners for direct or indirect heating;

- Pulse, proportional or combined power control;

- The systems using the combustion air heating in the central recuperator or systems using recuperative or regenerative burners, systems using air or water heating for technology production needs.

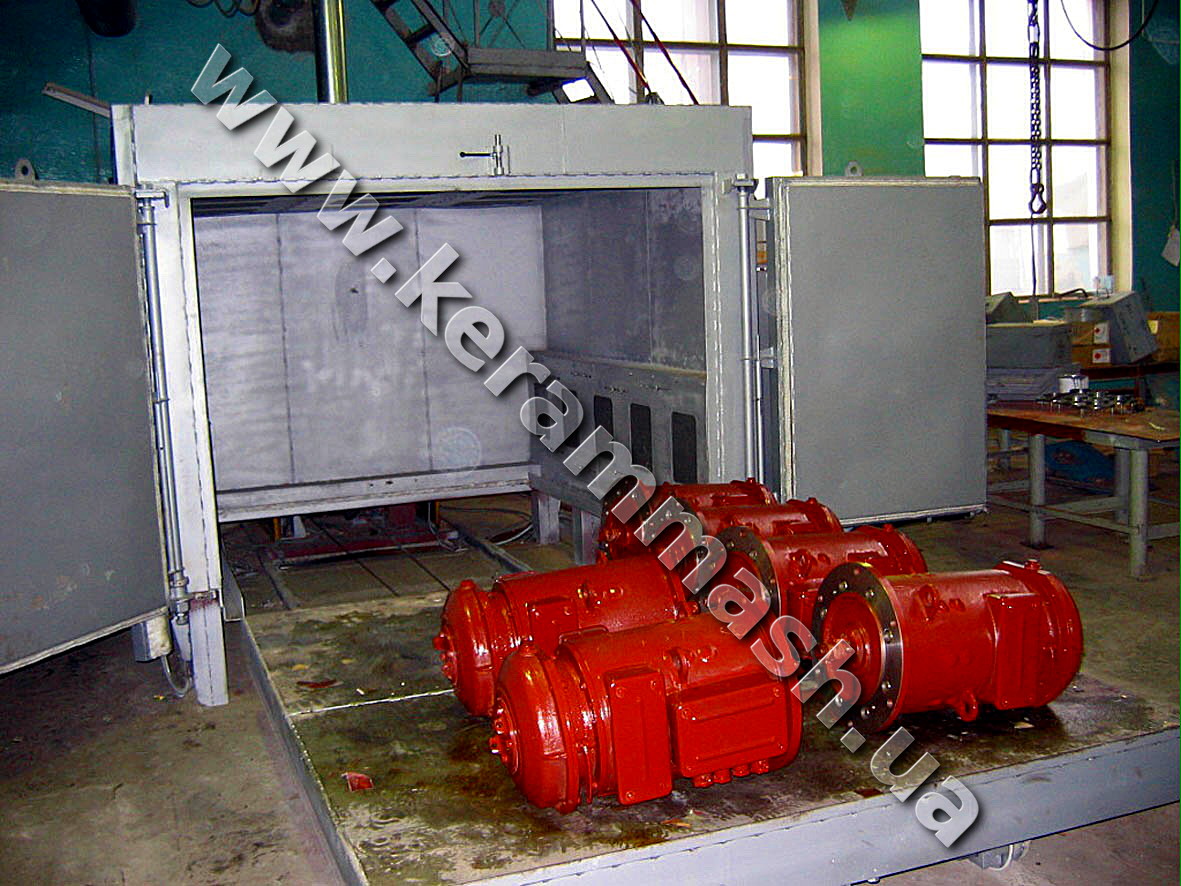

Series ТермоМастер ®

[ ThermoMaster ] — are the furnaces electrically heated with

indirect heating. Depending on the application, the operating temperature furnace may have different heating, control,

and energy-saving (lining) systems. In any case, the best, proven solutions provide high reliability heating elements,

easily replaced, thyristor power control system (pulse width or pulse-phase modulation) with microprocessor control,

effective refractory insulation (Nutec Europe, Thermal Ceramics, RATH, Calderis). Specially for high-temperature

furnaces series TermoMaster we developed special anchoring elements (the system "pipes and combs") providing the

reliability and durability of the fixing elements and heating elements alloyed FeCrAl in the application of ceramic

fiber materials for lining, ensuring finest furnace heat engineering parameters. Such systems are available only

on furnaces series TermoMaster.

Industrial furnaces for items and materials drying and calcination

(POTTERY, CONSTRUCTION MATERIALS, ELECTROTECHNICAL PORCELAIN)